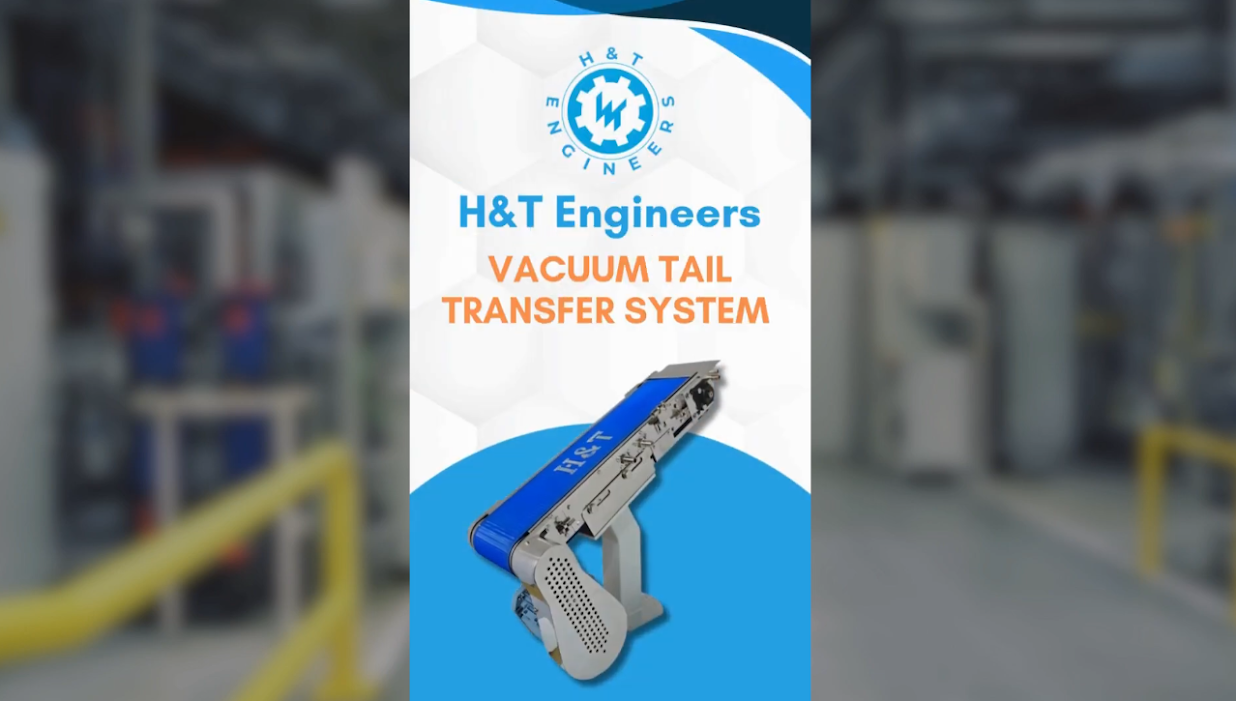

Vacuum Tail Transfer System

Purpose

The Vacuum Tail Transfer System (VTTS) is an innovative solution designed to thread the paper tail efficiently and safely from one section to another during tail threading in paper mills. Using high-velocity air and controlled vacuum suction on conveyor, the system guides the tail with precision—eliminating the need for manual intervention for paper tail transfers.

Application

- Paper Machines (All Paper Grades)

- Size Press Section

- Coating Section

- Calendar Section

- Pope Reel Section

Benefits

- High-Speed Machine & Efficiency

- Operator Skill Independent

- Enhanced Safety

- Minimized Downtime

- Cost-Effective Operation

- Easy to Maintain

- Consistent Performance

VTTS Components

Vacuum Conveyor

- Conveyor could be used on all paper machine, to thread a wide range of paper grades and basis weights.

- The Vacuum is supplied by external vacuum fan or through compressed Air in Venturi Option.

- The conveyor transports the paper tail from the Cutting tray device.

- A rotary parking arrangement as per machine space availability can also be designed.

Vacuum Blower

- Vacuum to conveyor is supplied by external vacuum fan connected through a pipe. A damper installed on Vacuum blower operated through sequential PLC programming switches vacuum on and off at conveyor.

- Not required for venturi option conveyor

Tail Cutting

- The pick-up plate stabilizes paper tail, pick up the tail from the dryer cylinder, cut and transferit to the conveyor.

Related Product

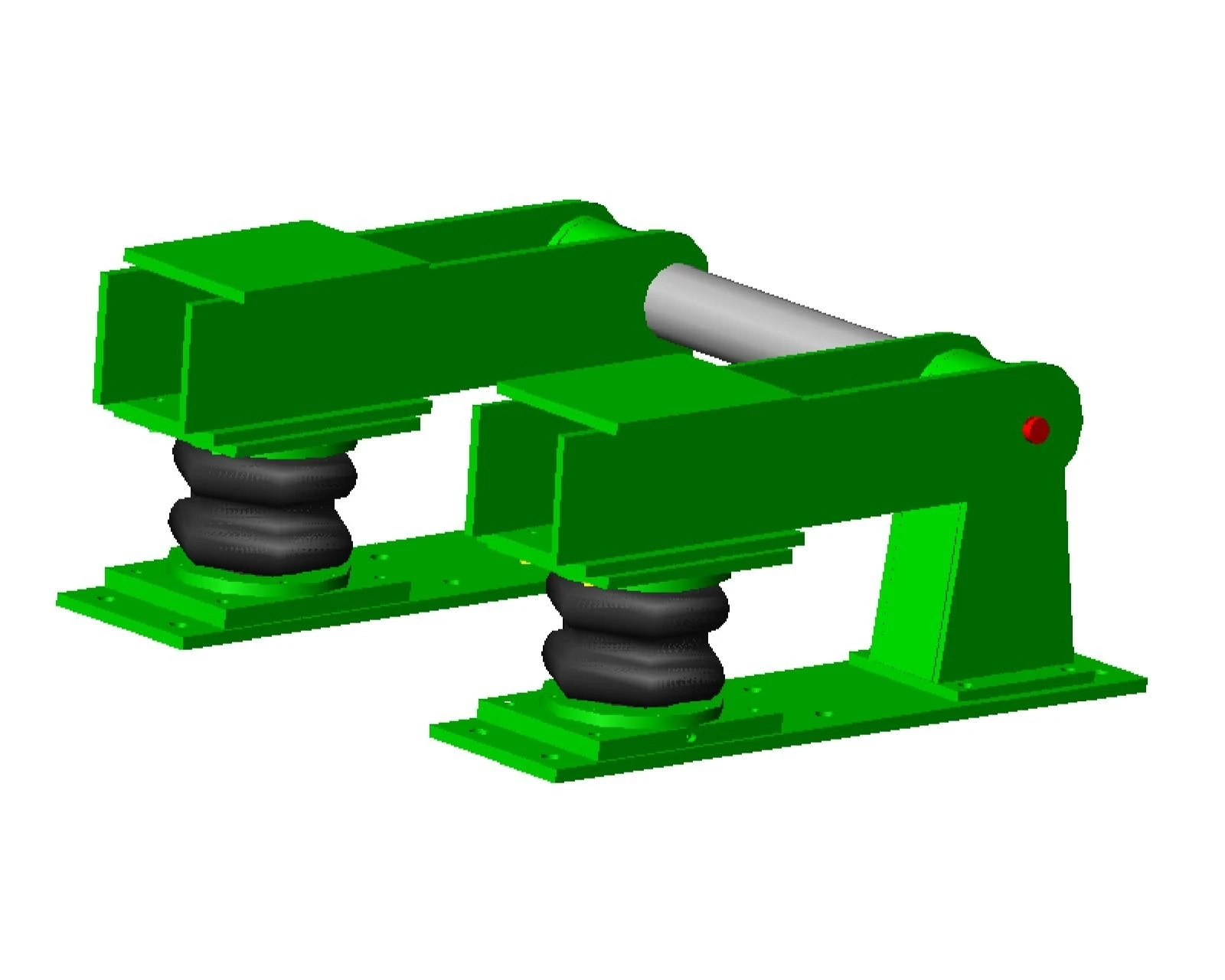

Auto Wire Tensioner

Tensioner works through pneumatic loading of double convolution rubber bellows supplied along with operating panel box. It maintains pre-set tension in wire.

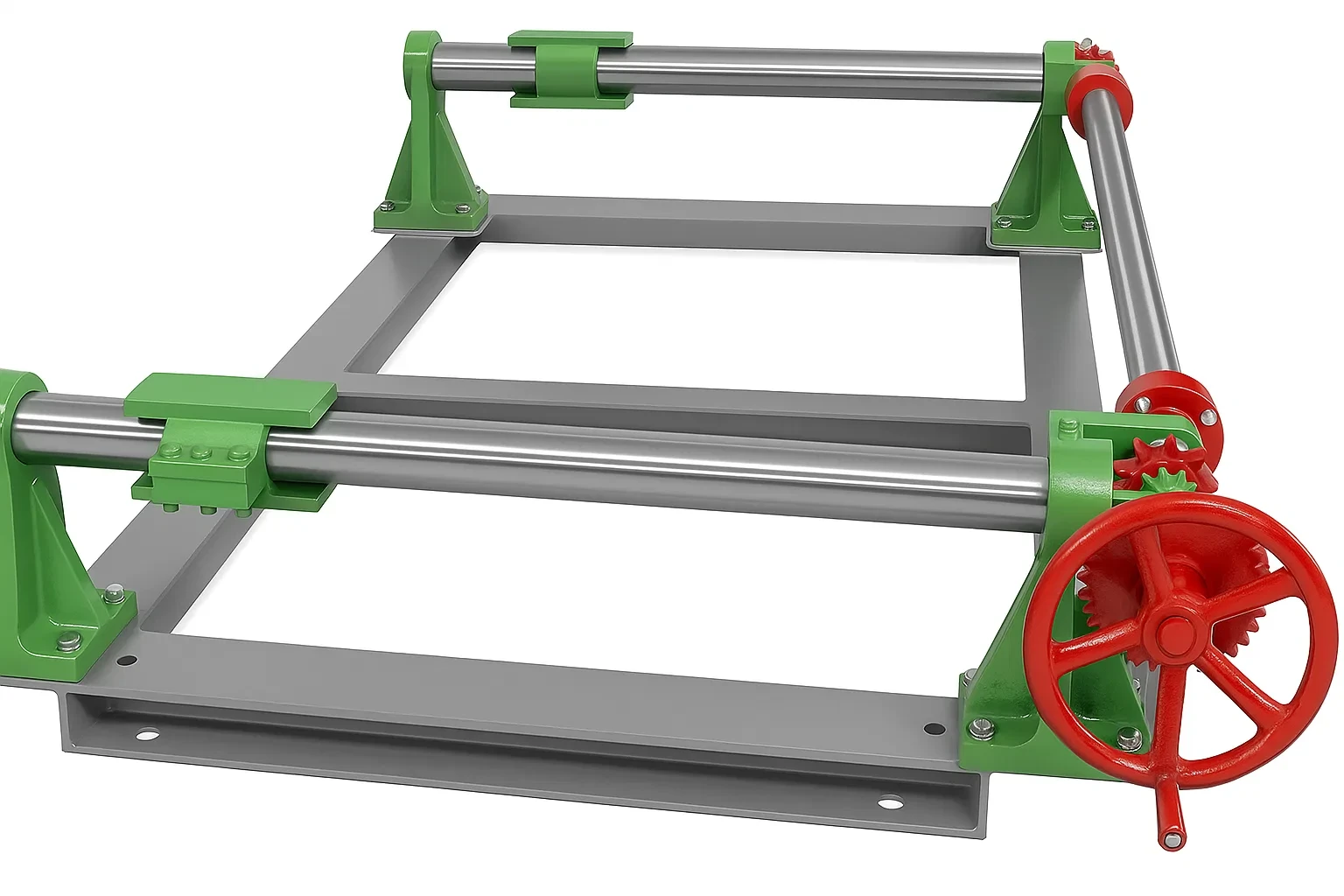

Double Felt Stretchers

These stretchers have been specially designed for long felts especially in duplex machine. Stretching achieved is four times the roll travel.

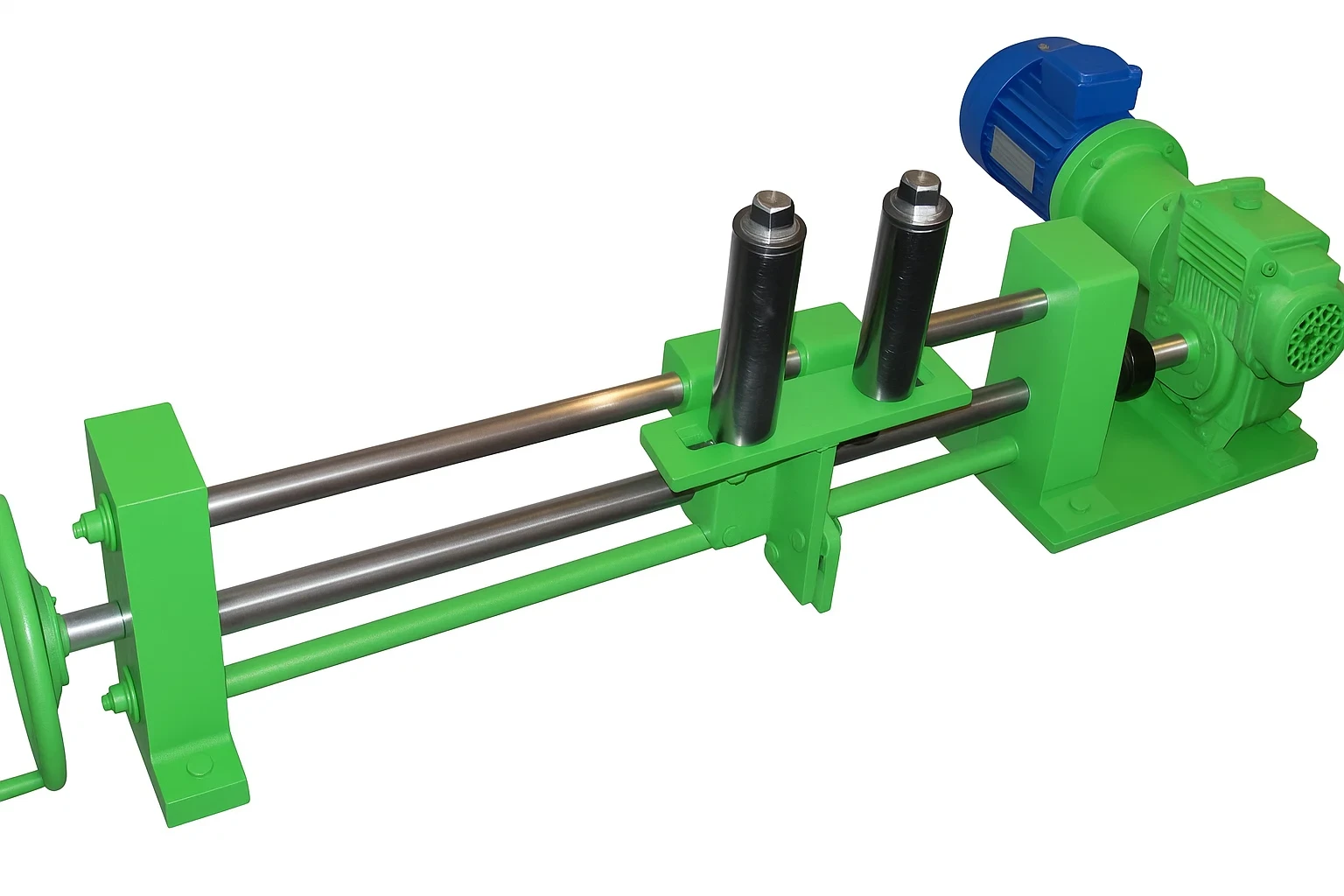

Electromechanical Belt Shifter

H & T Electro Mechanical Belt Shifter is normally used to shift belt over cone pulley drive to match the draw speed between different section.