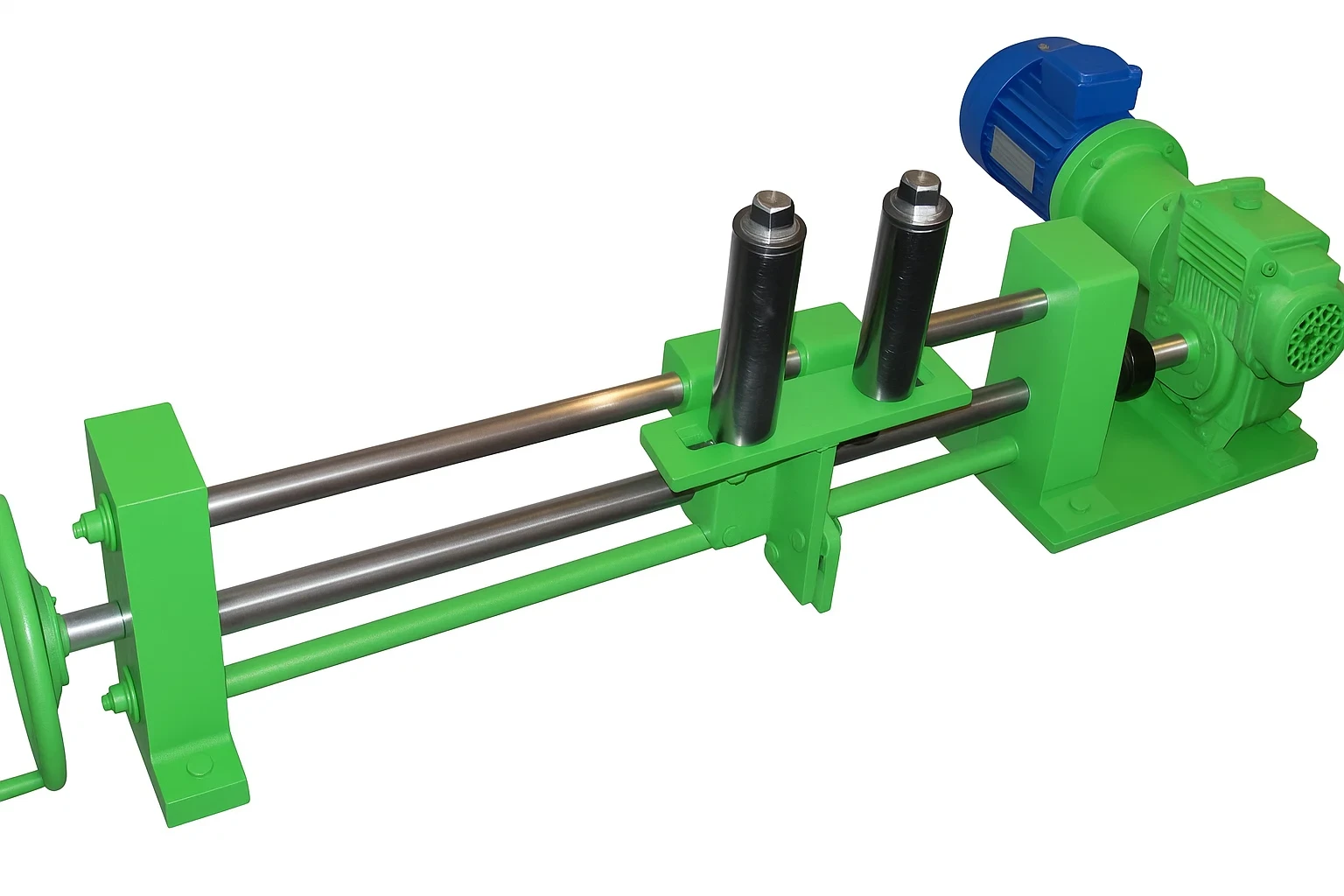

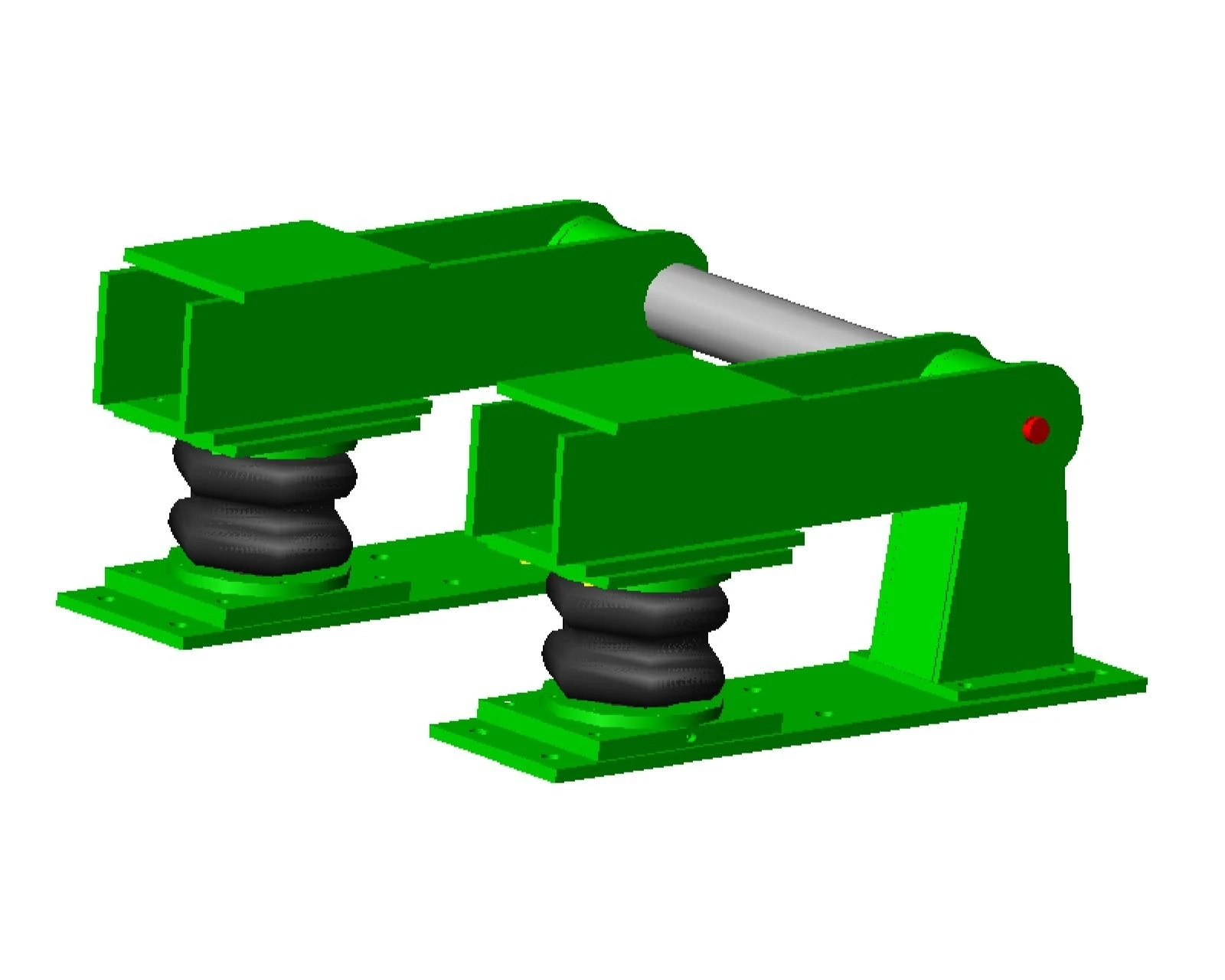

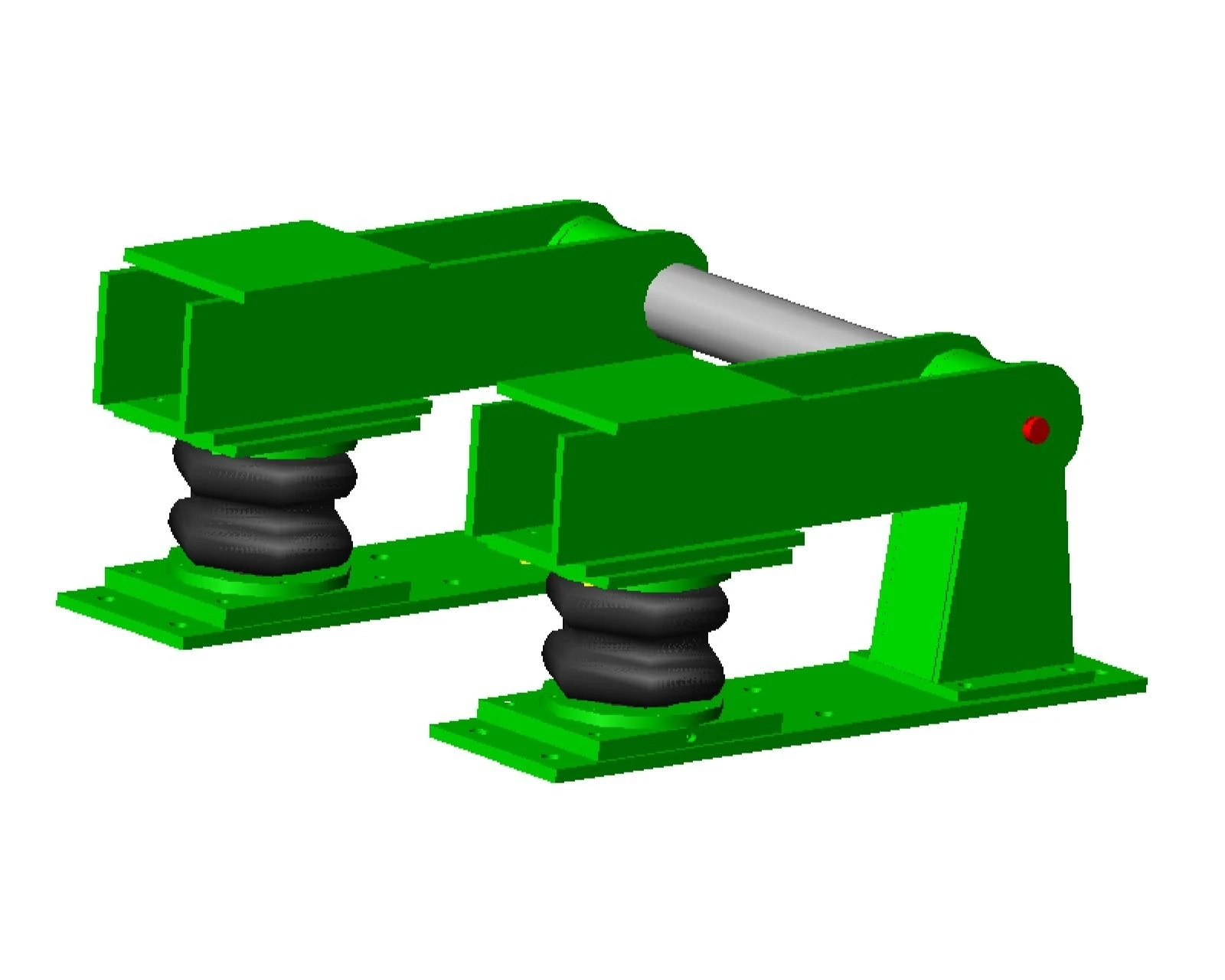

Auto Wire Tensioner

Tensioner with radial travel specially developed for the wet end of the paper machine.

Two members connected by a cross shaft guarantee parallel roll positioning.

Tensioner works through pneumatic loading of double convolution rubber bellows supplied along with operating panel box. It maintains pre-set tension in wire.

-

Vibration free tensioning mechanism for wire

-

Low Maintenance and robust design

-

Avoids wire slippage and improves efficiency

-

Maintains optimum tension in wire enhancing its life

MATERIAL OF CONSTRUCTION:

-

MILD STEEL

-

STAINLESS STEEL

SYSTEM ADVANTAGES:

-

Robust Design

-

High durability and Efficiency

-

Easy installation & removal

-

Low maintenance

Related Product

Auto Wire Tensioner

Tensioner works through pneumatic loading of double convolution rubber bellows supplied along with operating panel box. It maintains pre-set tension in wire.

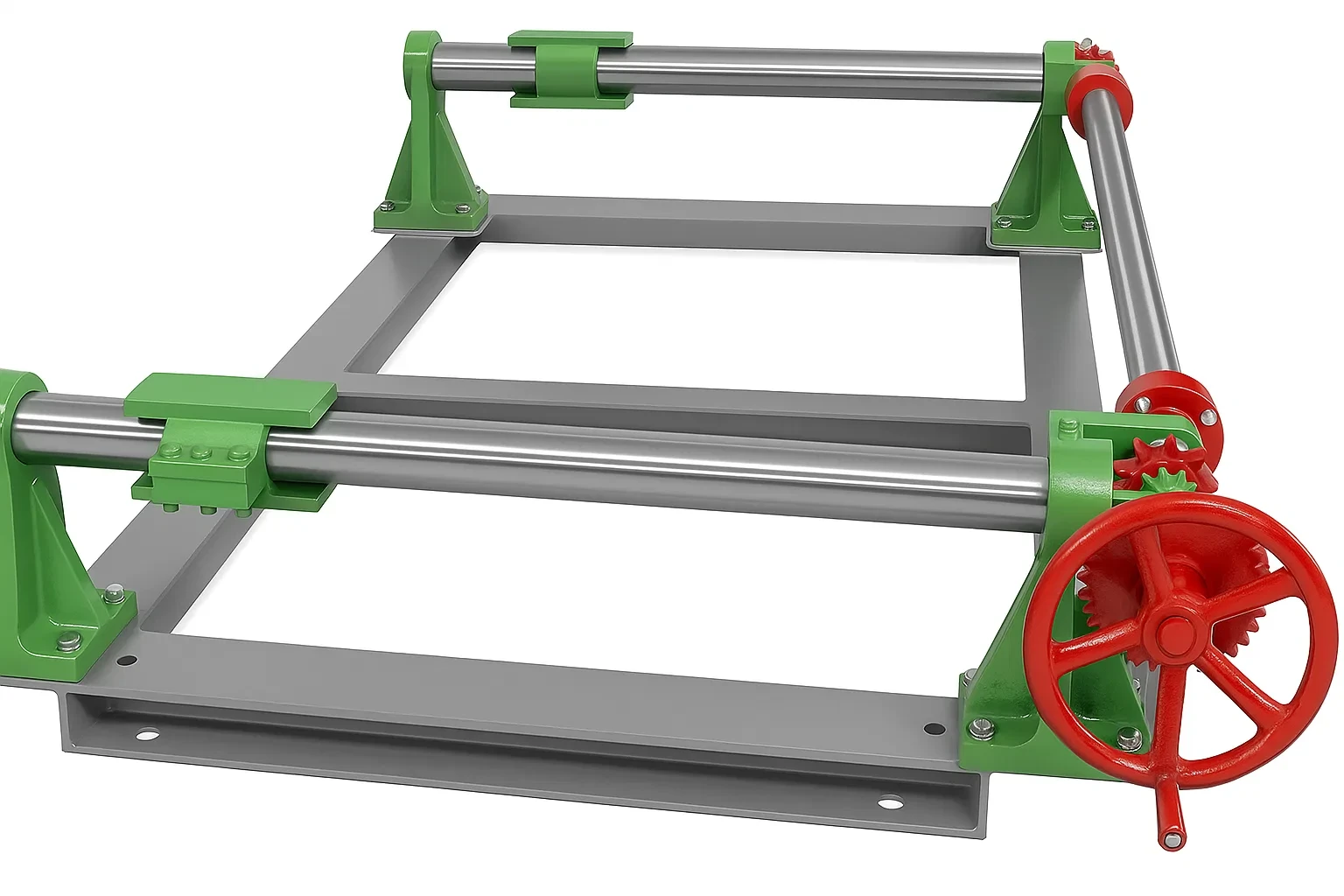

Double Felt Stretchers

These stretchers have been specially designed for long felts especially in duplex machine. Stretching achieved is four times the roll travel.

Electromechanical Belt Shifter

H & T Electro Mechanical Belt Shifter is normally used to shift belt over cone pulley drive to match the draw speed between different section.